Top 10 Air Compressor Dryer Installation Diagram

Nowadays, there are so many products of air compressor dryer installation diagram in the market and you are wondering to choose a best one.You have searched for air compressor dryer installation diagram in many merchants, compared about products prices & reviews before deciding to buy them.

You are in RIGHT PLACE.

Here are some of best sellings air compressor dryer installation diagram which we would like to recommend with high customer review ratings to guide you on quality & popularity of each items.

676 reviews analysed

Air Filter, 3/8" NPT wit Quick Release Bowl (Campbell Hausfeld PA212103AV)

- Cleans air and removes water vapor at the point of use to help support applications that require oil-free, moisture-free air, like spray painting. 3/8″ NPT

- The cleaner/dryer system includes a quick-release bowl for easily viewing the fluid level

- An oil-removal filter traps 99.9 percent of all oil aerosols and a desiccant system removes water vapor

- The outlet screen keeps desiccant particles from entering the airstream, protecting air tools

- Uses Campbell Hausfeld PA2086 desiccant packs. Finish your projects faster and easier with Campbell Hausfeld – The Air Power Expert

Product Description

The Campbell Hausfeld air cleaner/dryer system (PA212103AV) cleans air and removes water vapor at the point of use to help support applications that require oil-free, moisture-free, air-like spray painting. Two separate systems condition the air: An oil-removal filter traps 99.9 percent of all oil aerosols and a desiccant system removes water vapor. An outlet screen keeps desiccant particles from entering the airstream, protecting air tools. The desiccant changes color when it needs to be changed or recharged, providing an easily visible reminder. The cleaner/dryer system includes a quick-release bowl for easily viewing the fluid level and is protected against impact by metal guards. A quarter-turn drain makes maintenance easier. Finish your projects faster and easier with Campbell Hausfeld – The Air Power Expert.

From the Manufacturer

The PA2121, general purpose filter protects tools and equipment by removing most solid and liquid contaminants. This may include dust, dirt, pipe scale, rust, liquid water and bulk oil. A 5-micron filter element removes the smallest of particles. See-through bowl with metal guard allows easy monitoring of fluid level while protecting unit against impact. Features a quick-release bowl and quarter-turn drain for easier use. Standard series provides up to 57 SCFM flow capacity at 90 PSI. 150 PSI maximum pressure. 3/8-inch female NPT ports.

PneumaticPlus SAU430-N04DG-MEP Three Stage Air Drying System Particulate Air Filter, Coalescing Filter, Air Pressure Regulator Combo 1/2" NPT – Metal Bowl, Auto Drain, Bracket, Gauge

- Max. Supply Pressure: 250 PSI/ Max. Operating Pressure: 0-150 PSI

- SAF: 10 Micron Particulate Element, SAFM: 0.1 Micron Coalescing Element / Flow Rate: 37 SCFM @ 90 PSI

- Auto Drain, Metal Bowl w/ Sight Glass, Port Size: 1/2″ NPT

- Use Metal bowl in pressure exceeding 150 PSI or when solvents harmful to polycarbonate is present

- Pressure Gauge, Bracket Included

3/8" in LINE Desiccant AIR Dryer for Compressed AIR Great for Pneumatic Tools Spray Booth Plasma Cutter

- 3/8″ In-Line Desiccant Dryer with Beads, Clear Polycarbonate Bowl to check bead moisture at a glance

- 5oz Poly Bowl, 3/8 Female NPT Inlet and Outlet, Aluminum Quick Release Bowl Guard

- Beads turn from Blue to Pink when time to be changed.

- In-Line Desiccant Dryers are designed to remove moisture from your airlines.

NEW 1/2" Compressed Air Filter Regulator / Desiccant Dryer / Coalescing Filter 3 Stages Combo

- Particulate Filter: 0.05 micron filter will grab 95% of the large debris and moisture from your airline

- Regulator: 88 CFM Flow Rate, 215 PSI MAX Input, 150 PSI Max Output, Pressure Gauge included

- Coalescing Filter: 0.01 Micron Filter removes 99.99% of remaining debris and moisture left from the particulate filter

- 2 bags of desiccant beads

- Manual Drain

1/2″ Compressed air in line filter and desiccant air dryer and Coalescing Filter Three Stages combination Particulate Filter and Pressure regulator Combination: 0.05 micron filter will grab 95% of the large debris and moisture from your airline, 215 PSI Max Input and 150 Max Output, Polycarbonate Bowl allows you to view moisture levels at a glance, 88 CFM Flow Rate, Manual Drain. Coalescing Filter: 0.01 Micron Filter removes 99.99% of remaining debris and moisture left from the particulate filter. Desiccant Air Dryer: Come with 2 bags of desiccant beads

PneumaticPlus SAU3030M-N03G Three Stage Air Drying System – Air Particulate Filter, 0.3 Micron Coalescing Filter & Air Pressure Regulator Modular Combo 3/8" NPT – Manual Drain, Poly Bowl

- Max. Supply Pressure: 250 PSI, Max Operating Pressure: 150 PSI

- SAF:10 Micron Element Stanard/ SAFM: 0.3 Micron Coalescing Filter Element

- Manual Drain & Poly Bowl with Bowl Guard/Includes 0-150 PSI Pressure Gauge & Bracket

- Filtering out of dirt and foreign particles, and the separation of moisture is automatic with air flow. There are no moving parts and no adjustments are necessary. Accumulated sludge and moisture should be drained off.

- Manufacturerd In Korea

PneumaticPlus SAU320-N03G Compressed Air Filter Regulator Combo 3/8" NPT – Poly Bowl, Manual Drain, Bracket, Gauge

- Max. Supply Pressure: 250 PSI/ Max. Operating Pressure: 0-150 PSI

- 10 Micron Particulate Element / Flow Rate: 72 SCFM @ 90 PSI

- Manual Drain, Poly Bowl w/ Guard, Port Size: 3/8″ NPT

- Use Metal bowl in pressure exceeding 150 PSI or when solvents harmful to polycarbonate is present

- Pressure Gauge, Bracket Included

PneumaticPlus SAU430-N04G-MEP Three Stage Air Drying System Particulate Air Filter, Coalescing Filter, Air Pressure Regulator Combo 1/2" NPT – Metal Bowl, Manual Drain, Bracket, Gauge

- Max. Supply Pressure: 250 PSI/ Max. Operating Pressure: 0-150 PSI

- SAF: 10 Micron Particulate Element, SAFM: 0.1 Micron Coalescing Element / Flow Rate: 37 SCFM @ 90 PSI

- Manual Drain, Metal Bowl w/ Sight Glass, Port Size: 1/2″ NPT

- Use Metal bowl in pressure exceeding 150 PSI or when solvents harmful to polycarbonate is present

- Pressure Gauge, Bracket Included

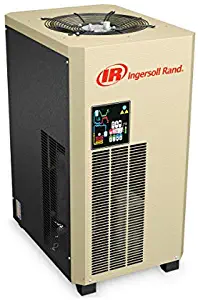

Compressed Air Dryer Refrigerated Type D42IN Scfm 25

- Reduced energy use: efficient heat exchangers, a built-in stainless steel demister that removes all moisture and a fully adjustable programmable electronic drain valve reduce energy use and minimize air loss

- Built-in Reliability: corrosion-resistant heat exchangers, an enhanced control-system and high-efficiency moisture-separation ensure a steady long-term supply of dry air

- Smart control: easy to use, Advanced microprocessor control that lets you easily adjust and manage system parameters

- Equipment protection: built-in coalescing filter stops contamination by separating water and oil from the compressed air

- Consistent clean, dry air: variable-speed fans reduce power consumption when units operate at less than maximum cooling capacity, while ensuring a consistent Dew point

Non-cycling refrigerated dryers deliver reliability with virtually No maintenance. Each Dryer features a refrigeration system and heat exchanger that combines Cool compressed air as it passes through it. These dryers integrate a unique combination of components and features that ensure maximum productivity and longest service life at an affordable cost.

PneumaticPlus SAU2030M-N02G Mini Three Stage Air Drying System, 1/4" NPT – Particulate Air Filter, Coalescing Filter, Air Pressure Regulator Combo – Poly Bowl, Manual Drain

- Max. Supply Pressure: 250 PSI, Max Operating Pressure: 150 PSI

- SAF:10 Micron Element Standard/ SAFM: 0.3 Micron Coalescing Filter Element

- Manual Drain & Poly Bowl with Bowl Guard/Includes 0-150 PSI Pressure Gauge & Bracket

- Filtering out of dirt and foreign particles, and the separation of moisture is automatic with air flow. There are no moving parts and no adjustments are necessary. Accumulated sludge and moisture should be drained off.

- Please use Metal Bowl option, when there is a presence of solvents harmful to polycarbonate. Manufacturerd In Korea

How It Works First, the air enter the particulate filter, which has 10 micron cleanable Polyethylene element. In this stage, corrosive moisture, pipe scale, dirt and rust are removed from air line protecting the precision part in the regulator. During Stage 2, fine filtration takes place. Here, 99.7 percentage of oil aerosols and microscopic particles down to 0.3 micron absolute are removed from the air. Third Stage, the air enter a high-performance regulator, which reduces primary pressure to a desired pressure setting. Installation Install units so the airflow is in the direction “IN-OUT” as indicated by arrow on the head of the unit. Install filter first in line of additional units such as regulators or lubricators, and as close as possible to the pneumatic tools or appliances being serviced. Unit must be installed in parallel from floor, downstream position for proper function. Do not install polycarbonate bowl in pressure that exceeds 150 PSI or where there is a presence of solvents harmful to polycarbonate. In these cases, use a metal bowl. The Unit can dis-assemble or assemble using a Phillips-head screwdriver or Allen wrench. An insert feature allows simple installation and removal in any location without disturbing the existing piping arrangement. The regulator can be mounted in either up or down position. This unique design allows unlimited adaptation to air preparation systems. Unit will permit use of standard size pipe nipples. Operation & Adjustments Filtering out of dirt and foreign particles, and the separation of moisture is automatic with air flow. There are no moving parts and no adjustments are necessary. Accumulated sludge and moisture should be drained off. Sediment should not be permitted to fill above the lower baffle. Wash filter element at intervals with methylene chloride or similar cleansing fluid to maintain filtering efficiency.

PneumaticPlus PPC3C-N03G 3 Stage Air Drying System – Particulate Air Filter, Coalescing Filter & Air Pressure Regulator Combo 3/8" NPT, Poly Bowl, Manual Drain, Embedded Gauge

- Max Supply Pressure: 250 PSI, Max Operating Pressure: 140 PSI, 16 SCFM @ 90PSI

- Particulate Filter: 5 Micron Element, Coalescing Filter: 0.3 Micron Element, Port Size:3/8″ NPT

- Manual Drain & Poly Bowl with Guard, Includes 0-140 PSI Embedded Pressure Gauge

- Use metal bowl in pressure exceeding 150 PSI or when solvents harmful to polycarbonate is present

- Manufactured in Korea

Conclusion

By our suggestions above, we hope that you can found Air Compressor Dryer Installation Diagram for you.Please don’t forget to share your experience by comment in this post. Thank you!

Our Promise to Readers

We keep receiving tons of questions of readers who are going to buy Air Compressor Dryer Installation Diagram, eg:

- What are Top 10 Air Compressor Dryer Installation Diagram for 2020, for 2019, for 2018 or even 2017 (old models)?

- What is Top 10 Air Compressor Dryer Installation Diagram to buy?

- What are Top Rated Air Compressor Dryer Installation Diagram to buy on the market?

- or even What is Top 10 affordable (best budget, best cheap or even best expensive!!!) Air Compressor Dryer Installation Diagram?…

- All of these above questions make you crazy whenever coming up with them. We know your feelings because we used to be in this weird situation when searching for Air Compressor Dryer Installation Diagram.

- Before deciding to buy any Air Compressor Dryer Installation Diagram, make sure you research and read carefully the buying guide somewhere else from trusted sources. We will not repeat it here to save your time.

- You will know how you should choose Air Compressor Dryer Installation Diagram and What you should consider when buying the Air Compressor Dryer Installation Diagram and Where to Buy or Purchase the Air Compressor Dryer Installation Diagram. Just consider our rankings above as a suggestion. The final choice is yours.

- That’s why we use Big Data and AI to solve the issue. We use our own invented, special algorithms to generate lists of Top 10 brands and give them our own Scores to rank them from 1st to 10th.

- You could see the top 10 Air Compressor Dryer Installation Diagram of 2020 above. The lists of best products are updated regularly, so you can be sure that the information provided is up-to-date.

- You may read more about us to know what we have achieved so far. Don’t hesitate to contact us if something’s wrong or mislead information about Air Compressor Dryer Installation Diagram.